Stainless steel handrail flush joiner is a component used to connect different sections of a handrail. It is typically made of stainless steel, which offers durability, corrosion resistance, and an attractive appearance. The flush joiner is designed to securely fasten the handrail sections together, ensuring stability and strength.

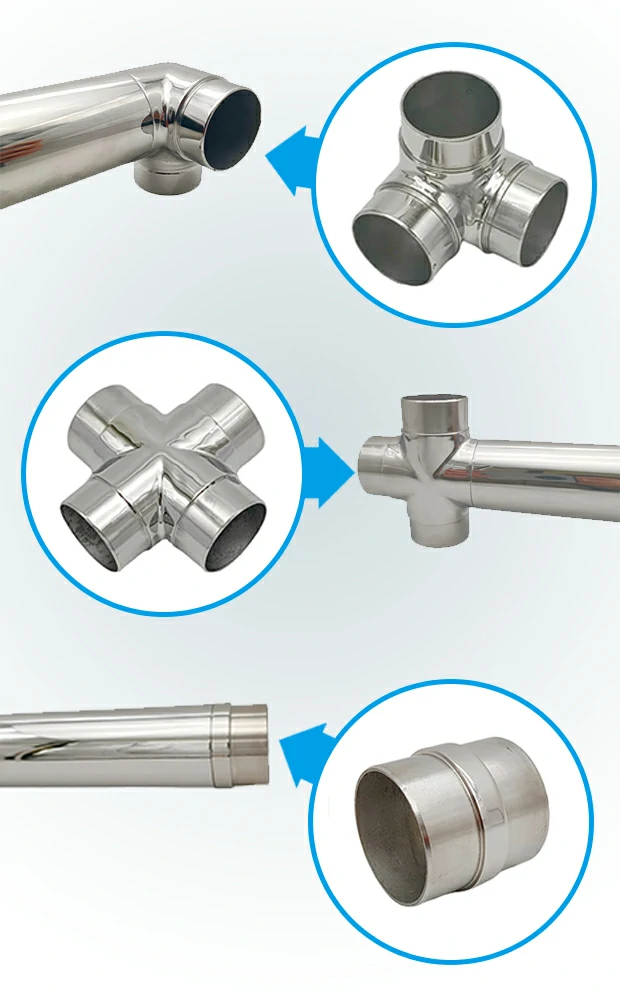

Some of the most common types of stainless steel handrail joiners include:

- End caps: End caps are used to cover the ends of a handrail. They can be decorative or functional, and they help to protect the handrail from damage.

- Connector brackets: Connector brackets are used to connect two pieces of handrail at a 90-degree angle. They are typically made of stainless steel, and they can be either welded or bolted to the handrail.

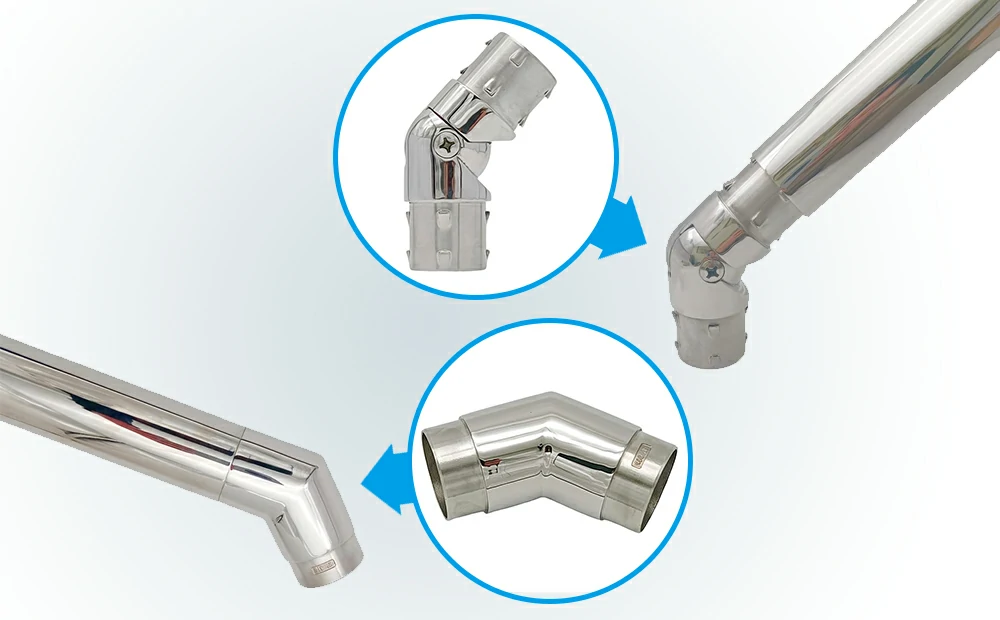

- Elbow connectors: Elbow connectors are used to connect two pieces of handrail at a 45-degree angle. They are similar to connector brackets, but they are designed to create a smooth, curved transition between the two pieces of handrail.

- Pivoting connectors: Pivoting connectors are used to connect two pieces of handrail that need to be able to move independently of each other. They are typically made of stainless steel or brass, and they have a pivoting mechanism that allows the handrail to move freely.

Why use tube joiners for handrial?

The joiner usually consists of two parts that fit over the ends of the handrail sections. These parts are then secured together using screws, bolts, or other fasteners. Some handrail joiners may also incorporate internal connectors or inserts to provide additional support and rigidity to the joint.

Overall, stainless steel handrail joiners play a crucial role in creating a seamless and robust handrail system, whether it's for residential, commercial, or industrial applications.

Tube joiners or connectors for handrails serve several important purposes:

- Easy Installation: Tube joiners simplify the installation process by providing a convenient method to connect handrail components without the need for complex welding or specialized tools. They allow for quick assembly and disassembly, making them ideal for both temporary and permanent handrail installations.

- Versatility: Tube joiners offer flexibility in design and configuration. They enable the creation of various handrail layouts, including straight runs, corners, angles, and staircases. By using different types of joiners, you can adapt the handrail system to suit specific architectural requirements and spatial constraints.

- Structural Integrity: Joiners ensure structural integrity by securely connecting handrail tubes or sections. They help distribute the load evenly along the handrail, enhancing stability and safety. Stainless steel tube joiners are particularly robust and durable, providing long-lasting support for the handrail system.

- Aesthetics: Tube joiners contribute to the overall appearance of the handrail. They create seamless connections between tubes, giving the handrail a clean and polished look. Stainless steel flush joiners, in particular, offer a sleek and modern aesthetic that is popular in many contemporary designs.

- Maintenance and Repair: In the event of damage or wear on a particular section of the handrail, tube joiners make it easier to replace or repair individual components without affecting the entire handrail system. This saves time and cost compared to more intricate welding or fabrication methods.

- Overall, Stainless steel handrail joiners for handrails provide practicality, versatility, strength, and visual appeal. They are widely used in various architectural and construction applications where reliable and aesthetically pleasing handrail systems are required.